LEAK TESTS FOR AUTOMOTIVE INDUSTRIES

Adlema, which offers various solutions for the leak tests required for the automotive industry, works with automotive brands and subcontractor manufacturers of the parts. Contact us for your needs and to learn about our solutions and applications.

Best For Automotive

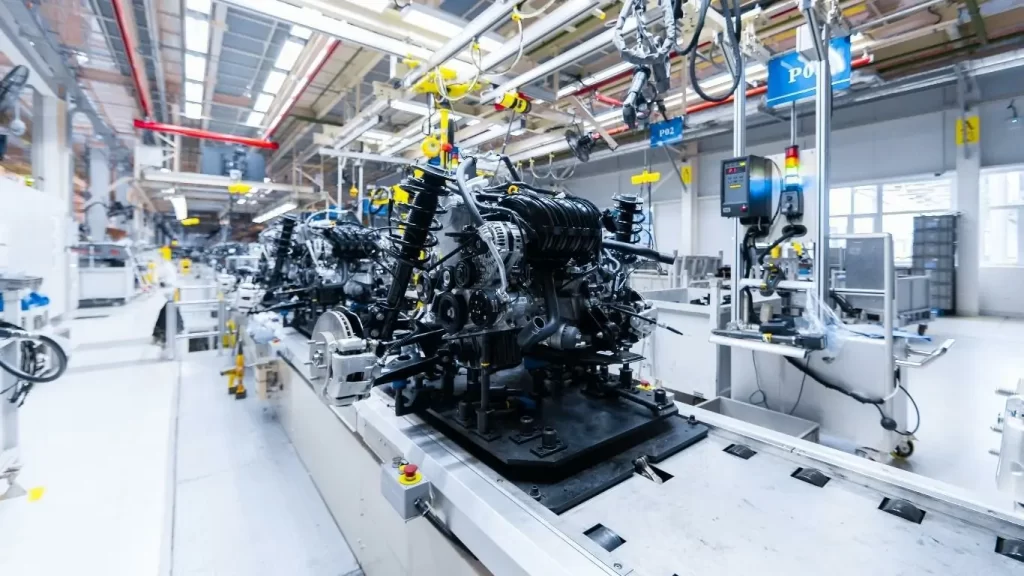

A standard automobile consists of more than 30,000 parts. There are parts of various sizes and shapes, made of several different materials in an automobile, from the engine blocks or fuel tanks, which are the largest parts, to tiny bolts. In order for an automobile to function properly and safely many of the parts must have leak proof property. Engine block or fuel hose that leaks is both a safety and a functional issue. Therefore, every product with leak proof property that comes off the manufacturing line must be tested.

In industries with high production rates such as the automotive industry, the pressure decay method is undeniably superior to the old-fashioned methods in the leak tests of manufactured products. This method complies with industry standards with its accuracy of 0.1 Pa and reportability.

Leak test is a non-destructive testing method (NDT) that can be applied to all products that comes off your production line, leaving no room for errors. With ADLEMA BT4000 Series Leak Testing Machines, you can perform leak tests in line with your production needs.

Trusted by:

We are stronger with you!

Products we test

Engine Parts

- Ball Bearing Leak Test

- Piston Leak & Volume Test

- Cylinder Blocks Leakage Test

- Cylinder Head Leak Test

- Cylinder Arm Leak Test

- Engine Block Leak Test

- Engine Gaskets Leak Test

Body Elements

- Condensation Tank Leakage Test

- Battery Leak Test

- Tire / Air Valve Leak Test

- Ecu Leak Test

- Vehicle Headlight Sealing Test

- Vehicle Headlight Bearing Sealing Test

- Horn Leak Test

Brake System

- Brake Disc Leak Test

- Brake Lines Leak Test

- ABS Brake Line Leak Test

- Brake Chambers & Knuckles Leak Test

- Brake System Leak & Pressure Test

Intake & Exhaust Systems

- Exhaust Pipe Leakage Test

- Air Filters Flow Test

- EGR Lines Leakage Test

- Exhaust Manifold Leak Test

- Limit Valve Leak, Flow & Function Test

- PCF Valve Leak Test

- Valve & Valve Guide Seals Leak Test

- Carburetor Leak Test

- Inter Cooler Leak Test

- Hose Leak Test

- Diesel Filter Flow Test

- Intake Manifold Leak Test

- Suction Line Leak Test

- Catalytic Converter Leak Test

- Silencer Flow & Leak Test

Fuel System Parts

- Fuel Cap Leak Test

- Injection Valve Leak Test

- Engine Combustion Chamber Leak & Volume Test

- Fuel Hoses Leak Test

- Valve Leak Test

- Fuel Injector Leak & Flow Test

- Fuel Tank Leak Test

- Fuel Tank Cap Leak Test

- Fuel Lines Leak Test

- Fuel Pump Leak & Flow Test

- Fuel Pump Control Valve Leak Test

- Manifold Leak Test

- Vent Valve Leak Test

Refrigeration & Air Conditioning Systems

- Refrigerant Line Leak Test

- Air Compressor Leak Test

- Air Conditioner Hoses Leakage Tests

- Evaporator Leak Test

- Condenser Leak Test

- Inter Cooler Leak Tests

- Water Line Leak Test

- Circulation Pump Leak Test

- Oil Cooler System Leak Test

- Thermostat Leak Test

- Radiator Sealing Test

Contact us today to meet our impermeability solutions specific to your industry!

Case Study

Leak Tests of Rubber Hoses with Banjo Fitting by Pressure Decay Method

Leak tests of rubber hoses with banjo fitting by pressure decay method are performed in two stages: the test of the banjo fitting and the test of the rubber hose. Rubber parts can be leak tested by pressure decay method. In the pressure decay method, the openings of the part are sealed with CZ Series Quick Connectors. Afterwards part is pressurized with predetermined test pressure. The pressure inside the part is monitored with 0.1 Pa accuracy and it is decided whether the part is defect-free or leaking in accordance with the predetermined parameters. However, using the pressure decay method is…