LEAK TESTS FOR THE DEFENSE INDUSTRY

Adlema, which offers various solutions for the leak tests required for the defense industry, creates value together with the defense industry companies such as Aselsan Precision Optics and Tubitak Sage. Contact us for your needs and to learn about our solutions and applications.

Best For Defense Industry

The use of leak tests is an important quality control method in an industry such as the defense industry, where high-tech products are used to operate in the most demanding circumstances. Every manufactured part is designed to work for longer periods of time in tougher conditions. Products need to maintain their physical properties in these tough conditions (leakproof property, IP67, hermetic property, etc.). Unexpected errors that occur in the field may cause fatal consequences. Hermetic property means that the electronic parts are packed in order to ensure their longevity.

The leakproof property of electronic components must be precisely controlled to prevent various gasses or specifically water vapor from damaging the electronic parts. In the leak tests performed with the pressure decay method, IP67 test parameters can be applied to all of these products that need to be resistant to dust, water or steam.

In applications where it is not desired for fluids and small particles to leak into or out of the product under various ambient conditions, leak tests should be performed using the pressure decay method. Leak test is a non-destructive testing method (NDT) that can be applied to all products that come off your production line, leaving no room for errors. With ADLEMA BT4000 Series Leak Testing Machines, you can perform leak tests in line with your production needs.

Trusted by:

We are stronger with you!

Products we test

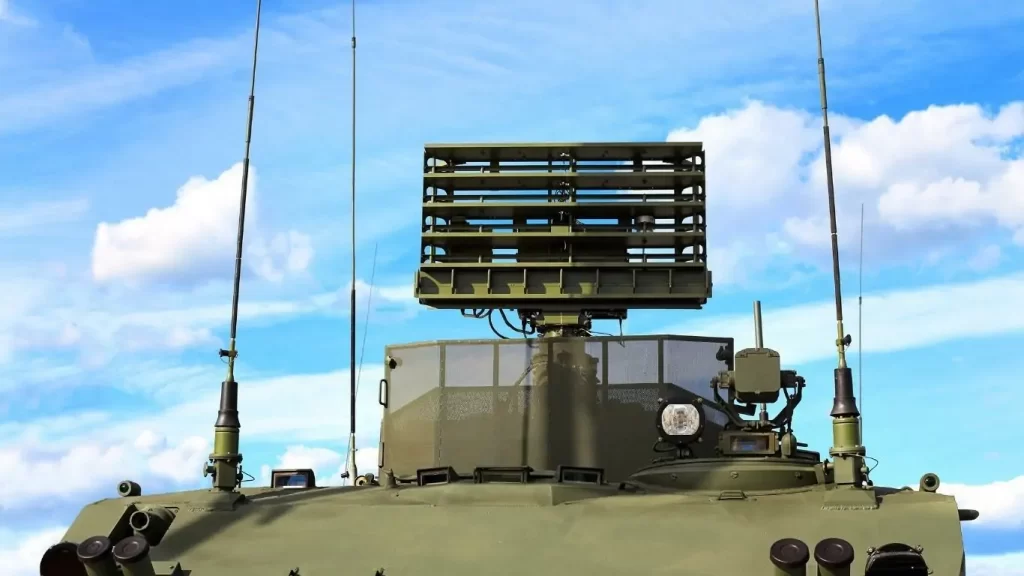

Military Vehicle

- Fire Extinguisher Equipment

- Refrigerant Pipes

- Cooling Systems

- Fuel And Engine Blocks

- Vehicle Headlights

- Vehicle Cameras And Electrical Circuit Boxes

UAV & AUAV

- Cameras And Other Optical Systems

- Electronic Components That Must Have Hermetic Properties

- Sensors

- Circuit Boxes

- Batteries

Electronics

- Batteries

- Electrical Circuit Boxes

- Radio Boxes

- Hermetic Parts

Aircraft

- Aircraft Engines

- Fuel Transfer Pipes

- Electronic Components That Must Have Hermetic Property

- Sensors

- Circuit Boxes

- Hydraulic Parts

Weapon

- Optical Weapon Attachments

- Night Vision Systems

- Thermal Cameras

- Helmet Vision Systems

- Missile Heads

- Guidance Kits

- Shell Casings

Sensors

- Sealed And Hermetic Sensors That Must Operate Reliably In Harsh Conditions