Conversion from Traditional Methods to Measurable Leak Tests

Conversion from traditional methods to measurable leak tests may at first glance seem like a more costly route. However, considering the long-term benefit, automated leak tests reduce the cost of production.

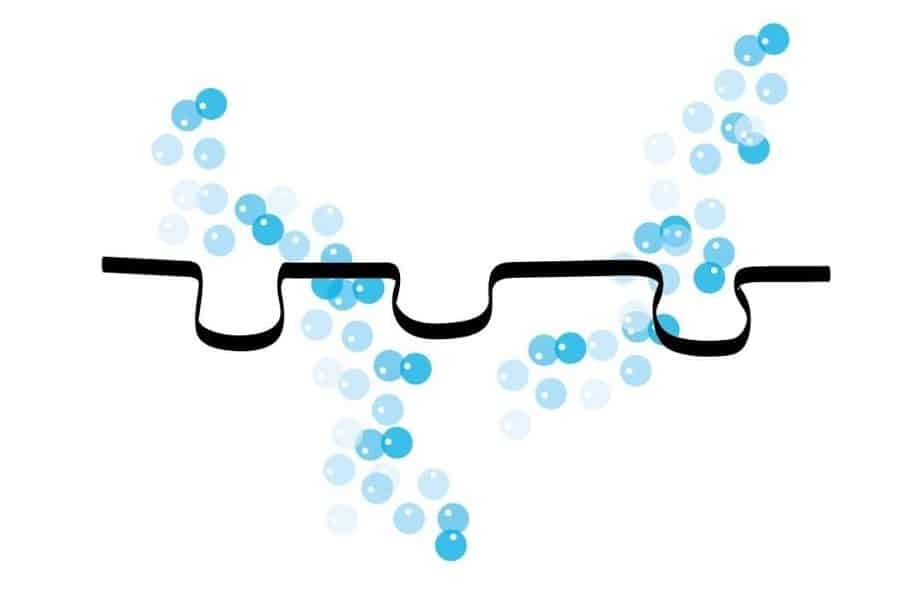

The traditional methods, namely the bubble method, is the simplest leak test method. If you have a container of water to test the product and a compressor to pressurize the product, this is sufficient. Then what you will do is wait for the bubbles to appear and count them.

Bubble monitoring method: Maximum leakage determined, bubbles counted manually. Limitations in control for mass production lines with increased probability of faulty products.

Traditional Method vs. Automatic Leak Tests

Since the leak tests performed with traditional methods are not measurable and are left to the operator’s subjectivity, it turns into a useless method, especially in mass production lines. Sending a faulty product to the end user can discredit your brand name and even cause harm to human life in sectors such as the medical and defense industry.

Automatic leak tests are non-destructive traditional testing methods. Your product will not be damaged while the tests are being carried out, and the tests are performed with precision. As the resulting OK/NOK decision is not the operator’s subjectivity, it provides objective accuracy. You can report with test data that you can use for measurement and traceability and repeat the test under the same conditions.

The leak test methods you can automate are the pressure decay, vacuum decay, or flow method. The design of the part, its volume, the maximum amount of leakage, the ambient conditions, and the cycle time help in choosing the leak test method that should be used.

Pressure Decay Leak Testing Method

For example, there are several factors that will affect the test time and test when performing leak tests with the pressure decay method.

- If the part you are going to test is flexible, the stabilization time should be long for an accurate test.

- If the volume of your part is large, more time is needed to test the product.

- If you need a sensitive leak test for your product, environmental conditions such as temperature change will affect the test to be performed. Contact us to get information about the solutions Adlema offers in this regard.

- No internal hole? Use EP60 for IP tests, pressurizing space between product and apparatus, monitoring external pressure decay.

The traditional methods are a good starting point for leak tests. But to build a credible brand image and develop a properly functioning quality system, you must improve your testing method.

Contact us to learn about our leak testers and the solutions we offer.