What is Pressure Decay Leak Testing

Pressure decay leak testing is one of the methods developed to check the leakage of products leaving the production line. In this method, the pressure is monitored at the level of 0.1 Pa and the leakage feature is tested with high precision, but it does not give any information about the location of the leak. Briefly, compressed air is supplied to the product and then the pressure decay in the product is measured. As a result of the measurement, a judgment is made about its leakage. Pressure decay leak testing saves companies from operator dependency and prevents operator-related errors. The method has the following steps in more detail:

- Pressurizing the product to be tested with dry air or nitrogen

- Separation of the gas-filled product from the pressure source

- Waiting in the so-called “stabilization phase” so that pressure differences due to pressure filling do not affect the test.

- Starting the test period after the stabilization phase

- According to the test parameters, the device automatically decides whether the product is leakproof or not.

- Discrimination of the product as “Not OK” or “OK”

The mentioned stabilization stage is the period of the disappearance of the expansion effect caused by filling it with air, depending on the type of product. The product, which is pressurized and inflated with gas, will expand a little after the gas contact is cut off and will maintain this state. Due to this, a pressure decay occurs. In order for the test not to be affected by this situation, the test period is started after this stage.

Effect of Ideal Gas Law

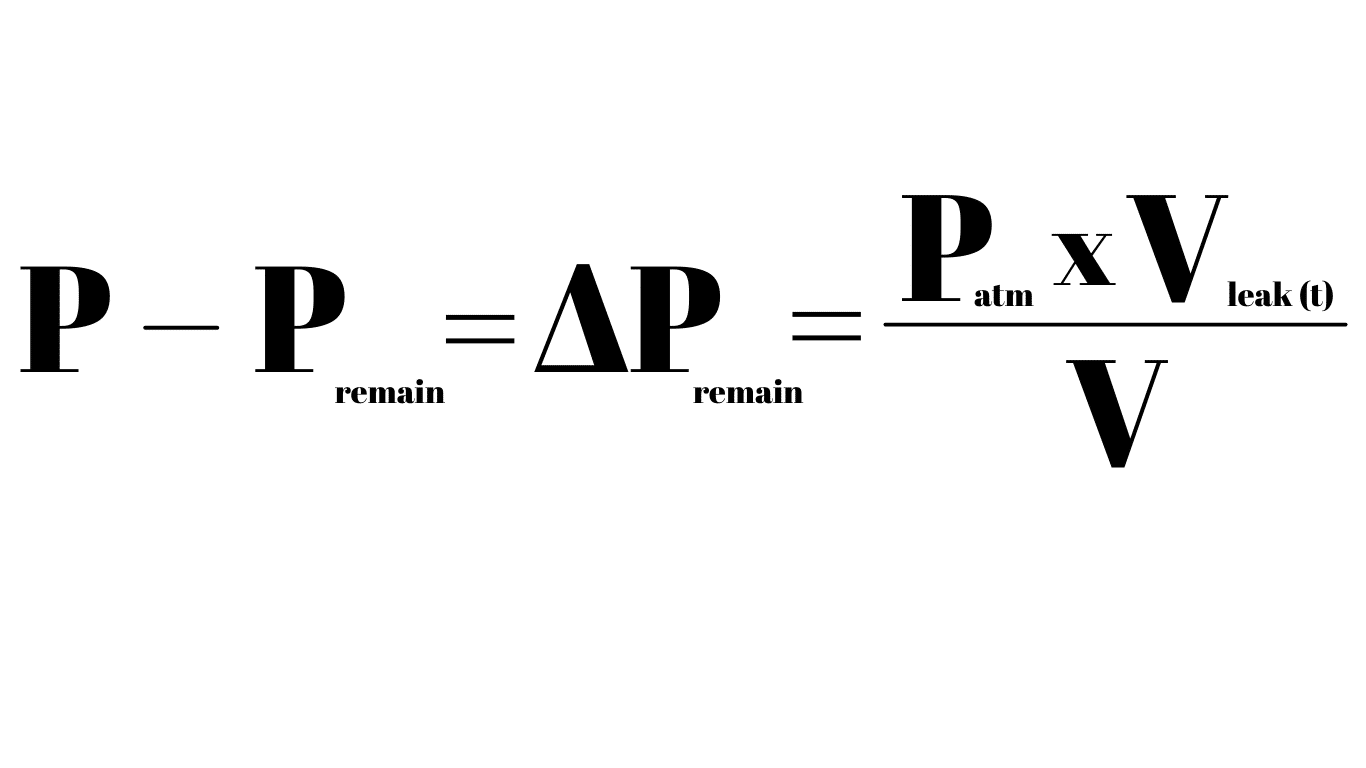

When testing the leakage of products using the pressure decay method, the reasons for the change in pressure should be examined. The pressure change is directly proportional to the temperature or the number of moles of gas. The law that explains this variation is the ideal gas law.

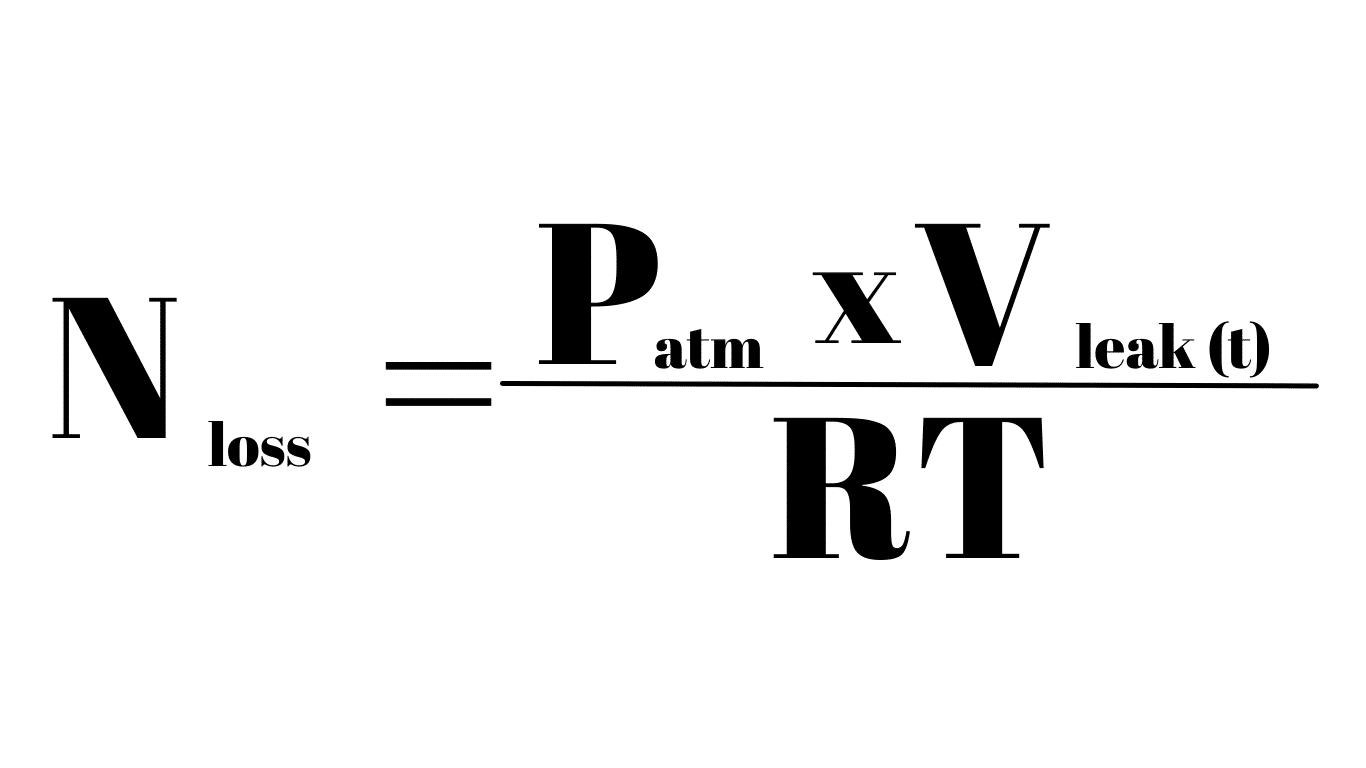

Nloss= number of moles of gas molecules coming out of the product

Patm =atmospheric pressure

Vleak(t)= The volume of gas released from the product to the atmosphere in 1 second

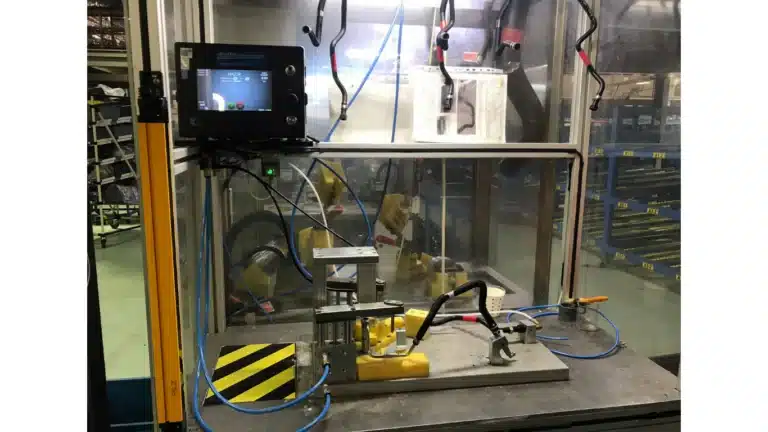

pressure decay leak testing

Nremain = number of moles of gas remaining in the product

Nremain = N-Nlost

P(remain) = Pressure of the gas remaining in the product

P(remain).V=Nremain.RT

P(remain)=Nremain.RT/V

Substituting the Nremain expression in the equation:

P(remain)=P-(Patm.Vleak(t))/V

If Vleak is taken from the pressure decay expression expressed depending on time;

pressure decay leak testing

If we want to calculate the sccm expression from the pressure decay;

It is calculated as follows in an application with 65 Pa/s and 80cc volume.

You can read our leak testing methods article to find out what other leak testing methods are.

For more information about pressure decay leak testing, you can contact us or review our other content.